Is a tailstock necessary when using a CNC lathe to machine a workpiece? The answer depends on the length of the piece. You can get by machining short-length pieces without a tailstock. However, a tailstock is vital to the CNC machining process to ensure accurately machining long, slender pieces — such as a rifle barrel — without distortion or chatter.

What Is a Tailstock?

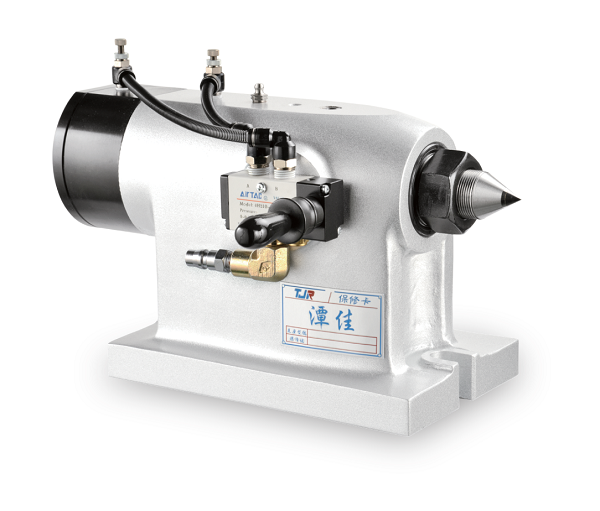

Located opposite the headstock on a CNC machine lathe, tailstocks are used to secure and support the free end of a workpiece while it is being machined. A tailstock ensures the work piece’s longitudinal rotary axis is held steady and fixed precisely parallel to the lathe bed.

The tailstock’s position is adjusted along the bed ways to fit pieces of different lengths. Once it is locked in place the tool is mounted and moved into the exact position using a leadscrew.

In addition to holding a workpiece in place, tailstocks are also used to drill out the centers of workpieces. A cutting tool, like a drill, tapper, or reamer, contained within the tailstock is used to create a hole of precise depth, shape, and diameter. However, unlike making holes with a drill press or milling machine, the tool within the tailstock remains stationary while the workpiece is rotated.

When Do You Need to Use a Tailstock in the CNC Machining Process?

Tailstocks aren’t required for every job, so when do you need to use one? Tailstocks are a necessity when machining long, slender pieces, but they’re also useful for shorter length pieces as well.

Most manufacturers recommend that you use a tailstock to support any piece that exceeds a 3:1 length-to-diameter ratio. The higher the length to diameter ratio, the greater the risks of flaws in the finished piece.

A piece with an LTD ratio of 2:1, say 2″ long and a diameter of 1″, could be produced without the need for a tailstock. Still, a tailstock can help prevent these pieces from becoming dislodged by securing them in place during machining. When LTD ratios exceed 3:1, a tailstock is a necessity to ensure the quality of the finished piece.

Alignment and Rigidity Are Critical to Proper Functioning

A tailstock must be properly maintained to ensure that it is accurately aligned with the headstock. When the tailstock is out of alignment, problems such as tapering and chatter (marks in the workpiece due to the part not being held tight enough by the tailstock) occur. The tailstock’s rigidity, its ability to securely hold a workpiece on center, has a big effect on the quality of the finished piece, too. Tapering, inaccuracies and other distortions can result when a tailstock isn’t properly secured.

Your Source for Tailstocks and Other Rotary Table Accessories

CNC Indexing & Feeding Technologies is your source for high-quality tailstocks and other rotary table accessories.

Since its founding in 2007, CNC Indexing & Feeding Technologies has grown to become a premier value-added importer/distributor of quality CNC machine accessories such as hydrodynamic magazine-style bar feeders, short bar loaders, and Gantry-style autoloaders.

Our TJR rotary and indexing tables let you turn any 3-axis machining center into a 4 or 5-axis one. In addition, we stock many accessories, including tailstocks and indexer controls.

CNC Indexing’s own brand of high-pressure coolant systems and Welltech-type oil skimmers improve part productivity and quality while increasing the shop life of your tooling and machines.

Give CNC Indexing & Feeding Technologies a call at 513-770-4200 or email us at sales@cncindexing.com to find out how our products can deliver on your manufacturing needs!