An indexing rotary table, also known as an indexing table, is a tool used to quickly and precisely rotate a workpiece so that a new edge is exposed for cutting. Among other things, indexing makes it possible to accurately manufacture large quantities of identical, interchangeable parts in a cost-effective manner.

When you decide to invest in an indexing rotary table, one of the biggest challenges will be finding the right indexing table to best suits the needs of your manufacturing operations. There are many factors to consider when making your decision, including cost, features, accuracy, functions, durability, etc. However, with a little research, you should have no difficulty finding an indexing table that fits your needs and budget.

Five Things to Consider When Shopping For a Indexing Table

Here are five things you need to consider when looking for the right indexing table for your needs:

Table Specifications

Table specifications are one of the most important things to consider. Be sure to take into account the maximum size of the workpieces you’ll need it to accommodate when deciding on the diameter needed for your indexing rotary table.

Power Sources

Indexing tables also have different power sources. Electrically powered indexing tables are the most popular type of indexing table and are available in many different versions. In many instances, electrically powered indexing tables are capable of faster indexing and can handle heavier loads than other types of tables.

Pneumatic indexing tables are driven by pneumatic cylinders. Hydraulic indexing tables are powered by pressurized hydraulic fluid. Then there are manual indexing tables, in which pieces are manually indexed using a hand crank.

Wormgear or Facegear Indexing Rotary Table?

Wormgear designs are the most popular indexing rotary table design on the market, providing a high level of flexibility with nearly infinite positioning options. Facegear indexing tables are generally used in dedicated applications and provide the extreme rigidity required for heavy cutting applications.

Drive Configuration

An indexing rotary table can have different drive configurations as well. There are cam index drives (the best choice when high speed indexing is required), roller gear index drives (ideal in situations where medium to high torque and right angle shaft orientation are needed), and ring index drives (highly versatile).

Indexing Rotary Table Mounting Options

You have three options when it comes to mounting: vertical, horizontal, or versatile. Vertically mounted tables come standard with 3 axes; they’re the most popular type. Horizontally mounted tables come standard with 5 axes. Versatile mounting options will allow you to tackle a wide range of projects.

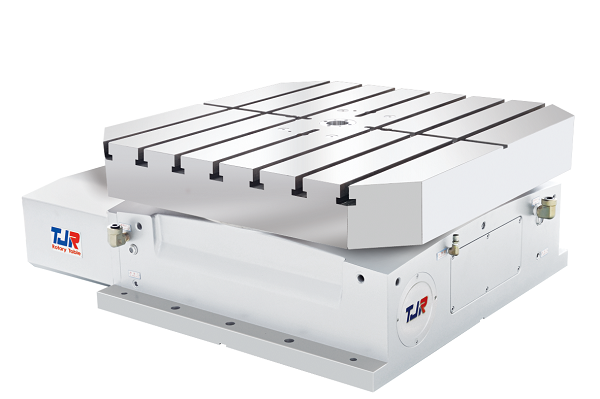

CNC Indexing & Feeding Technologies Has Just the Right Indexing Table for Your Operations

It doesn’t matter if you’re a small manufacturer or a large one; CNC Indexing & Feeding Technologies can help with finding the right indexing rotary table for your needs. This includes a full line of state-of-the-art TJR Precision Technology rotary tables.

Contact CNC Indexing & Feeding Technologies through our website or call us at (513) 770-4200 today to learn more about how our high quality indexing can increase your production capabilities, improve accuracy and reduce manufacturing cycle times.