An indexing table is a rotary table device that uses indexing to position a workpiece. CNC indexing tables are invaluable in milling and other industrial processes that require high precision cutting and shaping. They have a wide range of applications, including machining, positioning, inspection, and automation.

How Do Indexing Tables Work?

In manufacturing, indexing is the process of exposing a new edge or surface for use. An indexing table is used to convey and position workpieces during a manufacturing process.

The table’s indexing unit rotates the piece a precise distance into a specific position. It remains in place while the manufacturing tool cuts or drills the workpiece. Once the operation is completed, the table indexes the next section of the workpiece into position.

What Features Do Indexing Tables Have?

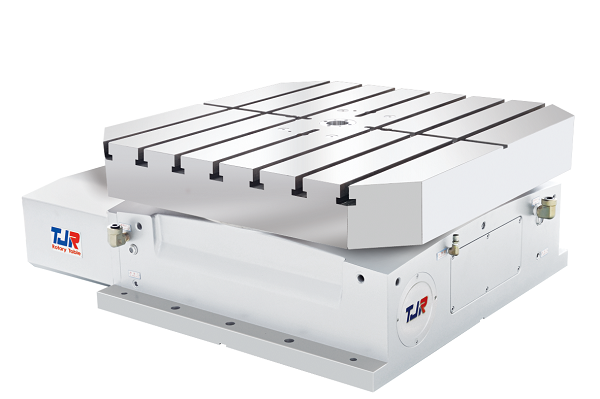

Indexing tables have a wide range of features. A basic indexing tool consists of a precision-machined steel plate with slots or mounting holes to secure workpieces during the machining process. They have either fixed or adjustable indexing angles. Parts can be loaded and unloaded manually or automatically.

There are three types of mounting: vertical, horizontal, and versatile. Indexing tables come with one or more spindles. Drive systems can be powered by pneumatic or electric motors, hydraulic drives, or even manually.

Today, most indexing is performed using CNC technologies. CNC indexing tables are faster and more precise than manual indexing.

Benefits of Using an Indexing Table

An indexing table is one of the most efficient ways to move and position a piece for precision machining. They can be used with small, medium, or large workpieces. Some of the benefits of using an indexing table include:

- Accuracy: Indexing tables allow for precision machining.

- Consistency: Precise indexing movement of the table ensures the production of a consistent product..

- Faster production: The design allows for faster production of workpieces.

- Increased profits: Faster production means you can produce more products in less time, which means increased profits.

CNC indexing tables are used in the machining process for parts and components in a wide range of industrial applications, including food and beverage, printing, aerospace, defense, construction, medical, and automotive.

CNC Indexing & Feeding Technologies is a Leading Importer/Distributor of Machine Tool Accessories

CNC Indexing & Feeding Technologies has been a premier importer/distributor of quality machine tool accessories such as hydrodynamic magazine-style bar feeders, short bar loaders, rotary tables, high-pressure coolant systems, and oil skimmers since 2007. Our line of TJR Precision rotary and indexing tables turn any 3-axis machining center into a 4 or 5-axis with customized faceplates available. In addition, we offer manufacturers our own CNC Indexing brand of hydrodynamic magazine bar feeders, short bar loaders, and gantry-style autoloaders.

If you’re looking for the best CNC accessories for your manufacturing operations, contact CNC Indexing & Feeding Technologies online or call us at 513-770-4200.