CNC Indexing & Feeding Technologies is proud to carry TJR Precision Technology rotary tables. All of TJR’s rotary tables incorporate a range of features that give them an edge over competitors, and the dual lead worm gear is at the top of the list.

How Does A Dual Lead Worm Gear Work?

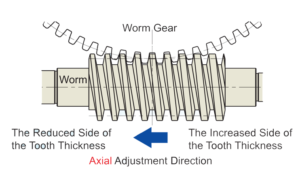

With the dual lead worm gear, one lead consists of a single flank of the worm thread and mating sides of the wheel teeth; the other flank and its mating wheel teeth are manufactured with a lead that is slightly different.

The result of this is a worm threat that increases in thickness from one end to the other, so that when it moves in an axial direction while in mesh with the wormwheel, backlash is adjustable from an acceptable maximum to zero.

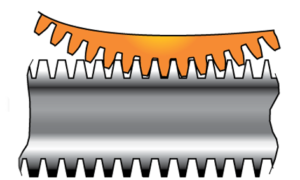

The one-piece dual lead wormshaft is more accurate than split types. The use of an oversize diameter pitch circle reduces pressure on the contact surface, and the worm gear uses a full tooth depth engagement paired with a larger gear module to create a larger surface contact area for a much stronger worm gear system.

The dual lead worm and worm gear featured in all TJR rotary tables are made from high tensile brass. With an estimated wear life of 10 years, they have more than twice the life of aluminum bronze components.

Disadvantages of Split Type Worm Gear Systems

The split type worm gear is a two-piece design in which the worm is split along the gearing centerline. In this configuration, one worm may be integral with the shaft, while the other is keyed to the shaft but adjustable along the axis with the position being fixed by a spacer positioned at the centerline between the two.

There are several issues with this design:

- The spacer requires a gap that can interrupt the line of contact.

- The applied pressure from both sides of the wormwheel teeth means increased friction and reduced efficiency.

No matter what type of rotary table you need, CNC Indexing & Feeding Technologies has something to suit your needs. Contact us today at sales@cncindexing.com to learn more!