- Show Sponsor: AMT – The Association For Manufacturing Technology

- Show Dates: September 12-17, 2022

- Show Location: McCormick Place • 2301 S Lake Shore Dr • Chicago, IL 60616 USA

Click here for visitor registration.

Click here to create a “My Show Account” to begin keeping track of booths that you want to visit, and be sure to add CNC Indexing Booth #338622!

Visitor Housing

Housing for IMTS Visitors is open! Book your hotel rooms through the official IMTS housing agent, Global Housing Solutions, powered by AMT, to receive the lowest rates over the show dates — guaranteed! Shuttle service is offered to/from the show for all official IMTS hotels except for those within walking distance to McCormick Place or the Midway airport properties.

IMTS is the premier manufacturing technology show in North America. More than 2,000 exhibiting companies occupy 1.2 million net square feet of exhibit space at the McCormick Place complex in Chicago, Illinois. IMTS is held every even-numbered year in Chicago and attracts more than 114,000 buyers and sellers from over 112 countries.

Visit CNC Indexing & Feeding Technology’s Showroom

Machines on Display in 2018:

| TRACER 20 | Hydrodynamic Magazine Bar Feeder for fixed headstock or sliding headstock CNC lathes Bar Diameter capacity: 3mm to 26mm (0.118″ – 1.023″) Up to 12′ Bar Length |

| TRACER 51V | Hydrodynamic Magazine Bar Feeder for fixed headstock or sliding headstock CNC lathes Bar Diameter Capacity: 3mm to 26mm (0.118″ – 1.023″) Up to 12′ Bar Length |

| TRACER 65V/80V | NEW!Hydrodynamic Magazine Bar Feeder for fixed headstock or sliding headstock CNC lathes Bar Diameter Capacity: 10mm to 80mm (0.393″ – 3.149″) 12′ Bar Lengths |

| TRACER Vs-65E | Servo Short Bar Loader Bar Diameter from 5mm to 65mm (0.25″ – 2.56″) |

| TRACER Vs-80L | Servo Short Bar Loader Bar Diameter from 8mm to 80mm (0.315″ – 3.15″) |

| TRACER Vs-105XL | Servo Short Bar Loader Bar Diameter up to Ø105mm (4.13”) |

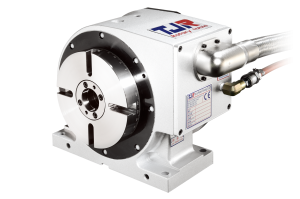

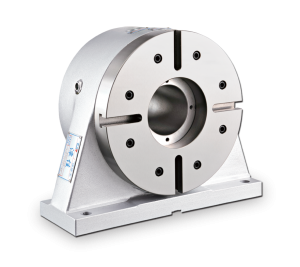

| AD-170 | Direct Drive Rotary Table |

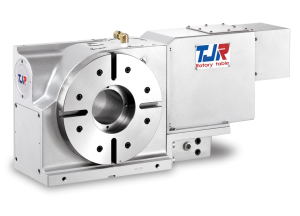

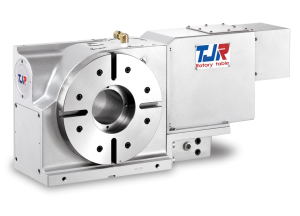

| AR-210R | Pneumatic Brake Standard Rotary Table Left, Right and Rear |

| HR-320R | Hydraulic Brake Standard Rotary Table Heavy Load Capacity |

| HR-630R | Hydraulic Brake Standard Rotary Table Heavy Load Capacity |

| HPC-400 | High Pressure Coolant System |

| HPC-1000 | High Pressure Coolant System |

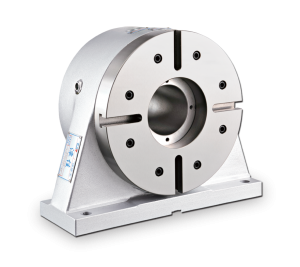

| RTA-170 | Rotary Tailstock Pneumatic or Hydraulic Brake System |

| RTA-210 | Rotary Tailstock Pneumatic or Hydraulic Brake System |

| TTJ-320 | Manual Tailstock |

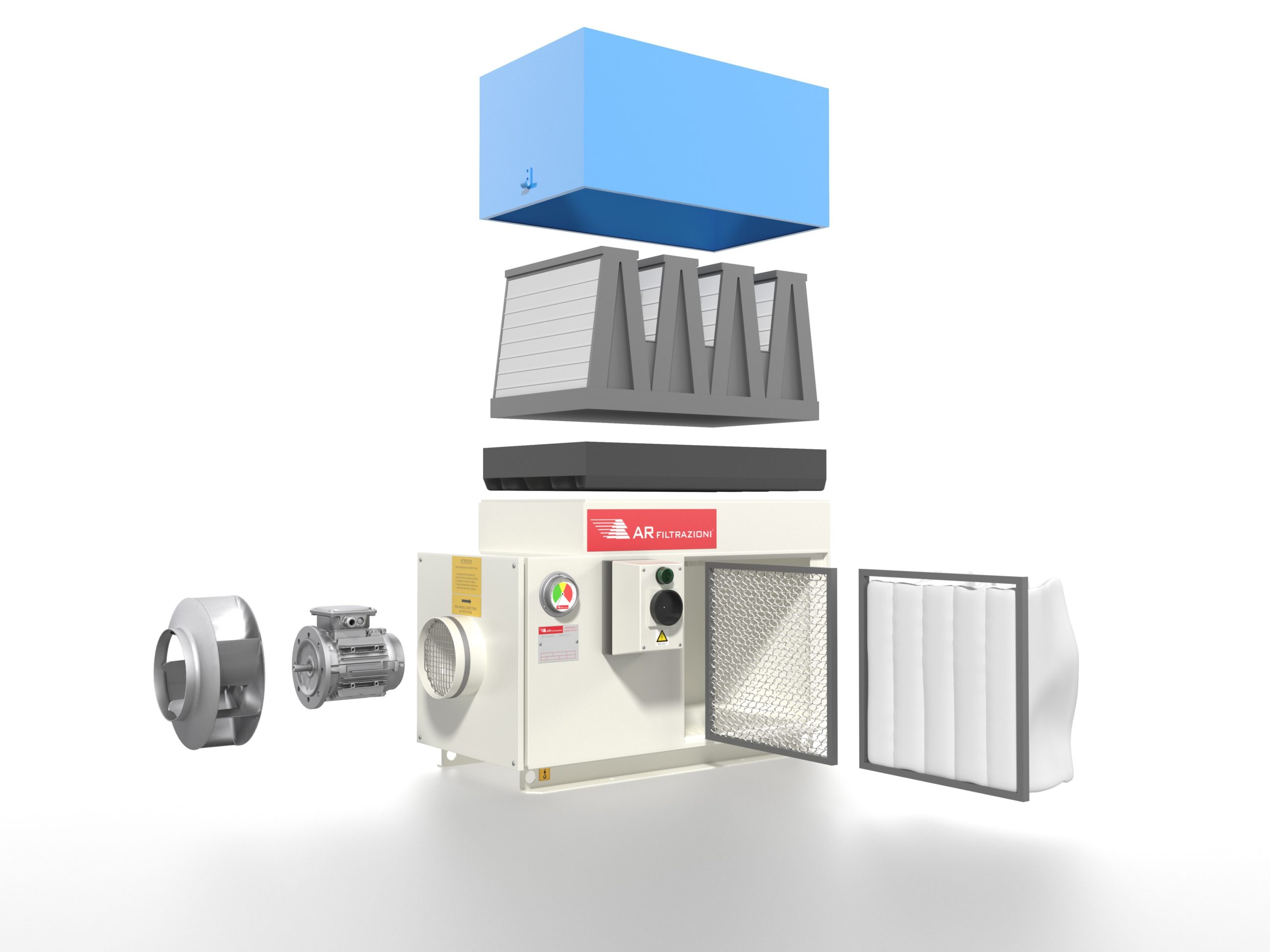

| ARNO 1-VF | Change is in the Air! The Arno 1-VF air filtration system from A.R. Filtrazioni is best suited for use with small to medium-sized CNC machine tools and operate best in heavy-duty high production machining environments that operate up to 3 shifts a day. Its airflow rate is 1000cfm / 1700m3h and is best used with water or oil emulsion or coolant. Known as the “workhorse model” it can have up to 6 stages of filtration. The first 5 stages of filtration are standard and include a self-cleaning centrifugal condenser, prefiltration cell made of galvanized steel metal filter, pocket filter with coalescence filter, and a second coalescence filter. The fifth stage uses a high-quality HEPA filter for final filtration. Add a pre-filter device and you’ve got 6 stages of filtration and the cleanest air of any shop. Weight of the unit is 154lbs. or 70kg. Image is 3d arno (1) attached to this task |

| ARNO 1-VF+PRF K1 | The Arno 1-VF+PRF K1 is the same unit as above but will include the pre-filter device for 6 stages of filtration. This option is best added for CNC machines that are equipped with high-pressure coolant pumps, horizontal machining center, and cutting with cast iron or aluminum. |

| K2-GM+PRF K23 | Change is in the Air! The Arno K2-GM+PRF K23 air filtration system from A.R. Filtrazioni is best suited for use with medium to large size CNC machine tools and horizontal machining centers, and operate best in heavy-duty high production machining environments that operate up to 3 shifts a day. These models are also best used in sliding headstock lathes with greater than 20mm bar capacity. Its airflow rate is 1700cfm / 3000 m3h and is best used with Neat oils. Neat oils (AKA cutting oils or straight oils) are water-undiluted mineral or vegetable oils blended with certain additives to generate certain beneficial properties. Their excellent lubrication and cooling properties make them particularly useful for reducing frictional heat, for example when a machine tool is processing a workpiece. This, in turn, contributes to giving the workpiece an appropriate surface finish, and helps prolong the life of the machine tool as well. As such, there are numerous industrial processes where neat oils are applied, ranging from light machining to heavy-duty operations. Among the more common applications are broaching, cutting, drilling, grinding, hardening, honing, milling and rolling (hot and cold). This unit has up to 6 stages of filtration. The first 5 stages of filtration are standard and include a self-cleaning centrifugal condenser, prefiltration cell made of galvanized steel metal filter, pocket filter with coalescence filter, and a second coalescence filter. The fifth stage uses a high-quality HEPA filter for final filtration. Add a pre-filter device and you’ve got 6 stages of filtration and the cleanest air of any shop. The K2-GM+PRF K23 units can be used with CNC machines tools that are equipped with a high-pressure coolant pump. Weight of the unit is 209 lbs. or 95 kg. |