Support longer and heavier workpieces

Support a tombstone or fixture plate to hold multiple workpieces

Become a more flexible shop

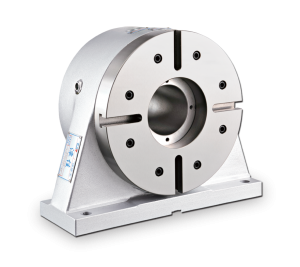

TJR Rotary Tailstocks

The rotary tailstock is ideal for applications that involve large heavy work pieces or for use with a tombstone or fixture plate. The rotary tailstock uses a pneumatic or hydraulic brake system to ensure the work piece or fixture remains rigid during the machining process.

Frequently Asked Questions About Tailstocks

Tailstocks are a machine tool accessory used to support long parts on lathe or rotary tables.

Maybe — depending on the size of the part. If a short-length piece is being machined, a tailstock may not be necessary. For a long, slender piece — such as rifle barrel — using a tailstock allows for more accurate machining without distortion or chatter. Read more

Use an indicator sweep of the tailstock quill, with the indicators mounted to either the lathe spindle or the rotary table faceplate. The center of the tailstock should be aligned with the center of the spindle if it comes from the factory. If added to a rotary table, the center height of the tailstock should align to the center height of the rotary table. Tailstocks can be adjusted side to side, but if the center height is off, add shims to adjust it higher or remove material to bring it lower.

There are manual tailstocks; automatic tailstocks, which may be hydraulic or pneumatic; tailstocks with built in live centers; and rotary table tailstocks, which looks more like a another rotary table and are built to support heavy parts.

There are:

– Dead centers, which do not turn and are typically used on manual machine tools and rotary table tailstocks.

– Live centers, which have built in bearings and are often used on CNC machines and when higher RPMs are needed.

| Model | Table Diameter mm / inch |

Center Height in Vertical mm / inch |

Overall Height in Vertical mm / inch |

Thru-hole mm / inch |

Width of T-slot mm / inch |

Width of Guide Block mm |

Clamping Force kg*m/ft*lbs. |

N.W. kg / lbs. |

| RTA-125 | Ø125 / 4.92″ | 110 / 4.33″ | 187 / 7.36 | Ø125 / 4.92″ | 12h7 | 14h7 | 13 | 18 /40 |

| RTA-170 | Ø125 / 4.92″ | 135 / 5.31″ | 230 / 9.05″ | Ø125 / 4.92″ | 12h7 | 14h8 | 31 | 29/64 |

| RTA-210 | Ø125 / 4.92″ | 160 / 6.29″ | 265 / 10.43″ | Ø125 / 4.92″ | 12h7 | 14h9 | 31 | 35/77 |

| RTA-250 | Ø125 / 4.92″ | 160 / 6.29″ | 285 / 11.22″ | Ø125 / 4.92″ | 12h7 | 14h10 | 35 | 57/126 |

| RTA-400A | Ø125 / 4.92″ | 255 / 10.03″ | 455 / 17.91″ | Ø125 / 4.92″ | 12h7 | 14h11 | 115 | 106/234 |

| RTH-210 | Ø125 / 4.92″ | 160 / 6.29″ | 265 / 10.43″ | Ø125 / 4.92″ | 12h7 | 14h12 | 35 | 35/77 |

| RTH-255 | Ø125 / 4.92″ | 160 / 6.29″ | 287.5 / 11.31″ | Ø125 / 4.92″ | 12h7 | 14h13 | 70 | 57/126 |

| RTH-320 | Ø125 / 4.92″ | 210 / 8.26″ | 370 / 14.56″ | Ø125 / 4.92″ | 14h7 | 14h14 | 115 | 83/183 |

| RTH-400 | Ø125 / 4.92″ | 255 / 10.03″ | 455 / 17.91″ | Ø125 / 4.92″ | 14h7 | 14h15 | 200 | 106/234 |

| RTH-500 | Ø125 / 4.92″ | 310 / 12.20″ | 560 / 22.04″ | Ø125 / 4.92″ | 14h7 | 14h16 | 200 | 199/438 |

| RTH-630 | Ø125 / 4.92″ | 400 / 15.74″ | 715 / 28.14″ | Ø125 / 4.92″ | 14h7 | 14h17 | 200 | 243/535 |

| RTH-800 | Ø125 / 4.92″ | 470 / 18.5″ | 885 / 34.84″ | Ø125 / 4.92″ | 14h7 | 14h18 | 200 | 247/544 |